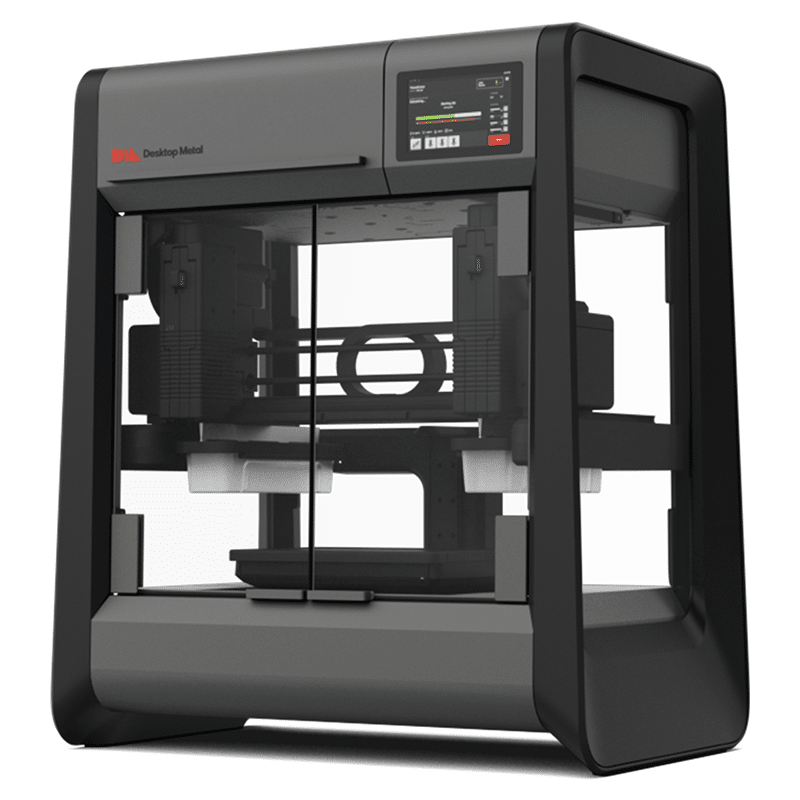

The Studio System was designed from the ground-up for simple installation and use. Its process is similar to the safest, most widely used 3D printing process—Fused Filament Fabrication (FFF). Unlike laser-based systems that selectively melt metal powder, the Studio System™ printer extrudes bound metal rods, eliminating requirements associated with metal 3D printing and enabling new features like closed-cell infill for lightweight strength.

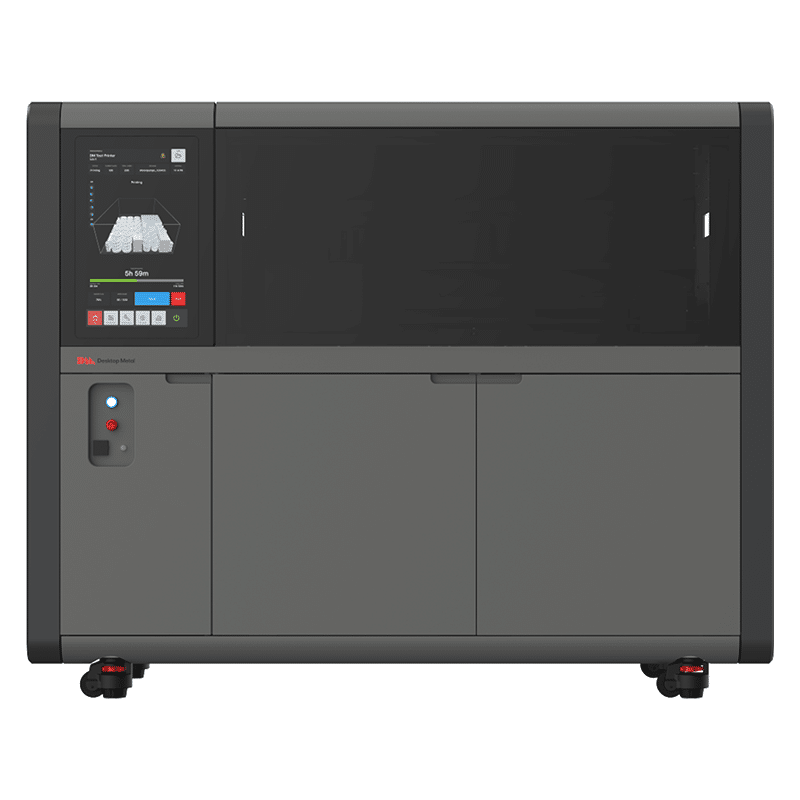

Print and sinter The Studio System features a simplified, easy-to-manage two-step process

Eliminates separate solvent debind phase

Place printed parts directly into the furnace

Nearly hands-off experience.

Software-controlled workflow Entire process (Printing and Sintering) is fully software controlled to achieve excellent parts

Auto print/sinter orientation optimization

Automatic, anti-locking supports

Automated thermal debind and sintering cycles

Process notifications

Job queueing for high throughput

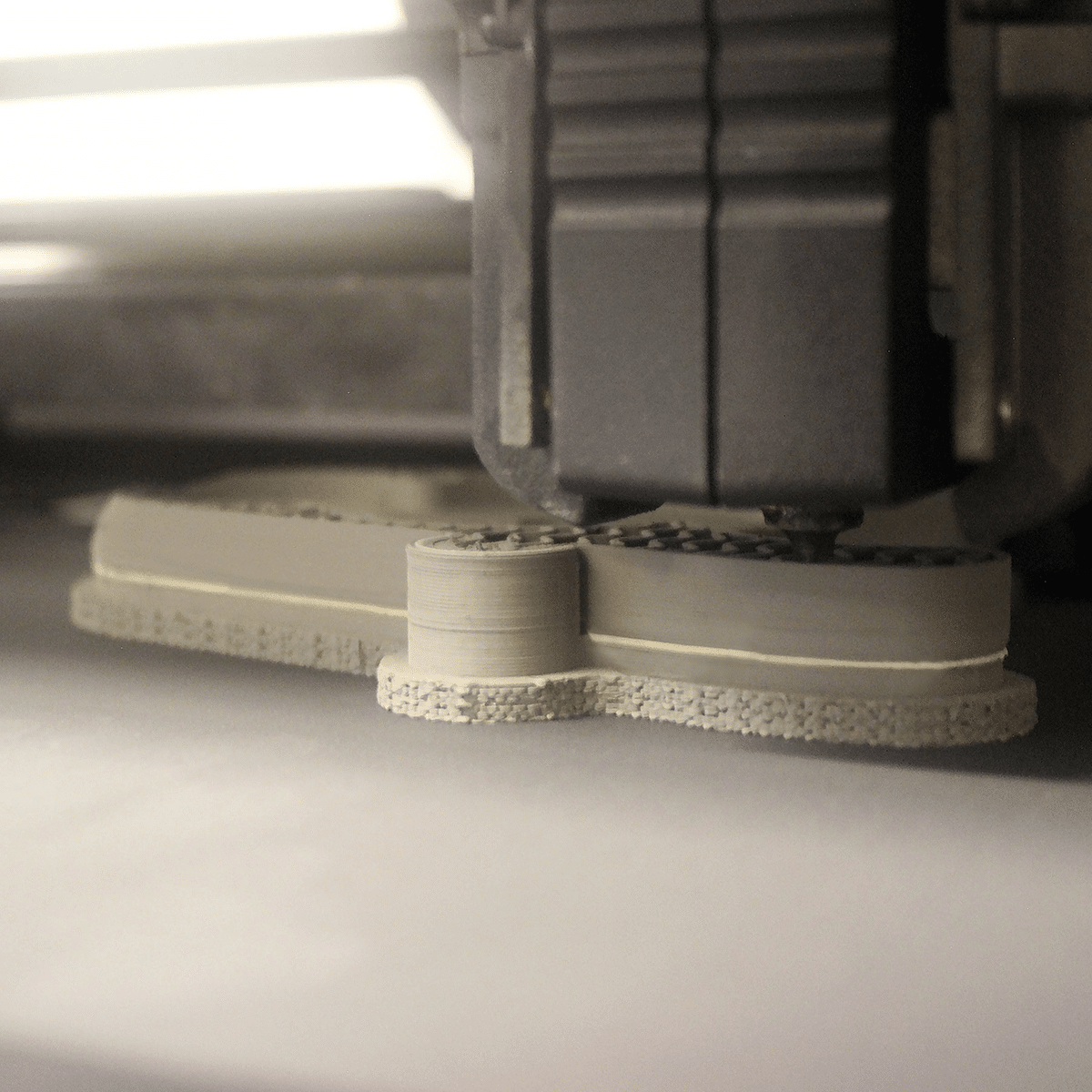

Smart Separable Supports™ Next-generation Separable Supports enable greater design freedom than ever before.

Software-generated support structures

Strategic splits in supports enable hand-removable supports and prevent locking

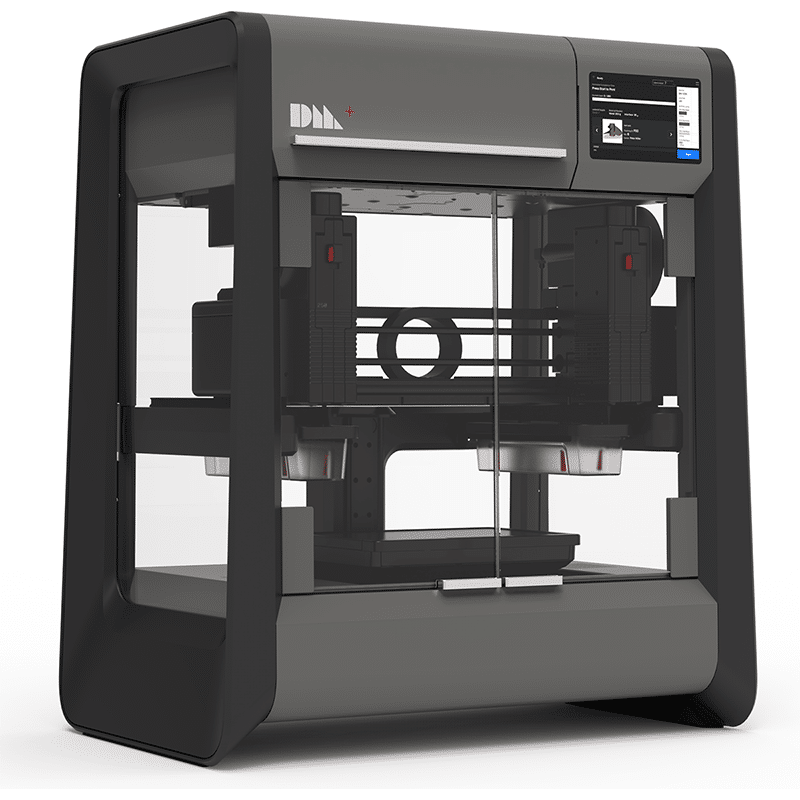

User-friendly hardware Intuitive, easy-to-use UI walks the users through the fabrication process, making printing and sintering seamless

Easy material changes

Push-to-release printhead changeover

Fully accessible printer and sintering volume

Cartridge system for materials

Reliable processing With major process and materials improvements the Studio System is designed to deliver parts consistently the first time.

Excellent first-time part success, reducing the trial-and-error process common with other metal manufacturing processes

Re-engineered interface layer material for more even shrinkage during sintering and increased part success across an array of geometries

Excellent part properties Leveraging decades of Metal Injection Molding (MIM) technology, the Studio System 2 delivers the material properties required for demanding applications. The bulk sintering process allows for homogenous microstructure, critical for end use parts.

Material properties exceeding Metal Powder Industries Federation (MPIF) standards

New gyroid infill creates strong parts, ideal for end-use applications

Customizable print settings With a process based on FFF printing, the Studio System 2 offers dozens of parameters for fine-tuning, making it easy to tailor parts to your exact needs.

Built-in profiles make build preparation as easy as a few clicks

Over 90+ settings available for adjustment

Adjustable shell thickness

Multiple printhead resolution, 250 µm & 400 µm

Adjustable layer heights, 50 um to 300 um

No special facility requirements The Studio System 2 is designed to fit easily into an office environment.

No solvents or loose metal powders

No third-party equipment required

Easy to install

Standard power requirements

System fits through standard doorways

2 pieces of equipment for minimal footprint

Print from your desk The Studio System’s easy-to-use design allows you to regain ownership of your production pipeline.

Designed for hands on use by your whole team

The system sits in the space where you work

No highly-trained operators required

Process based on FFF printing

Familiar design guidelines and best practices