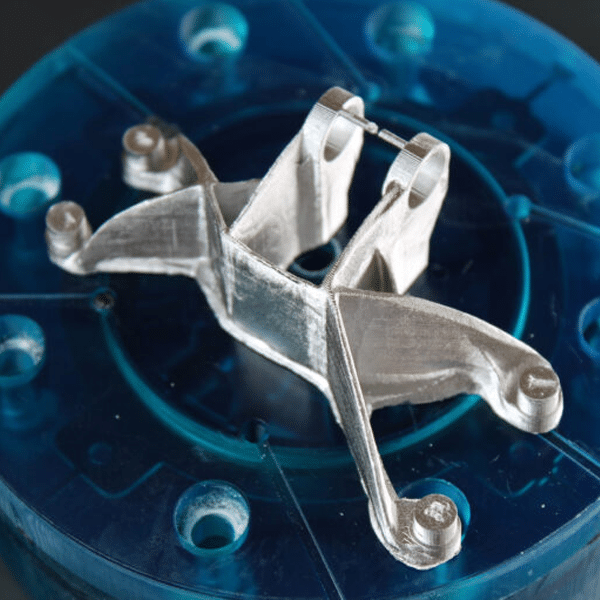

Acquire precision and detail with 3D printed patterns for casting. Whether you need patterns for rapid prototyping or production for an investment casting process, you can seamlessly integrate them into dip-shell or flask-type investment casting. Reduce costs in material and finishing time with patterns that deliver superior detail for investment casting.

Casting patterns are an ideal solution for foundry production of small, large, or complex metal parts. 3D printed patterns offer a faster, more accurate alternative to traditional pattern production methods.

A few examples of 3D Casting applications:

Whatever 3D printing needs your company has, we have the solution that will work best for you. We are proud to offer top-quality printers, supplies, and software, as well as end-to-end support and service.