Mosaic’s Element 3D printer enables multi-material & multicolor printing (up to 8). Element HT excels in high-strength applications with a 500°C hot-end and heated chamber. Fully automated with CANVAS and Mosaic materials.

UltiMaker S8 Pro Bundle achieves up to 4x the productivity of its predecessor allowing you to create complex multi-material parts in a fraction of the time.

UltiMaker S8 achieves up to 4x the productivity of its predecessor allowing you to create complex multi-material parts in a fraction of the time.

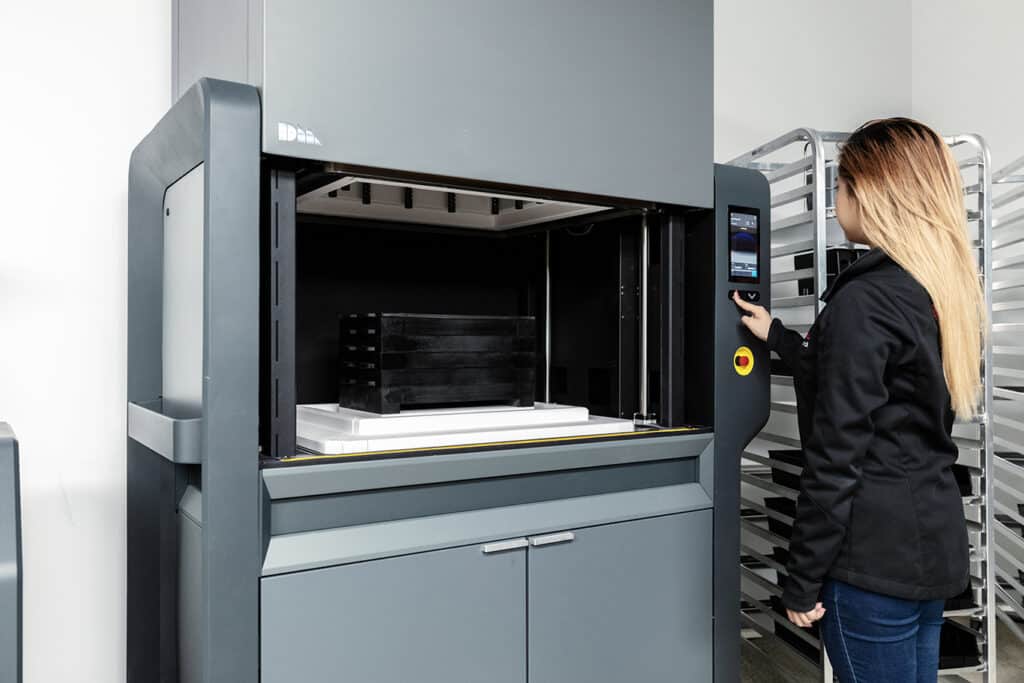

3D Printing Solutions

Whatever 3D printing needs your company has, we have the solution that will work best for you. We are proud to offer top-quality printers, supplies, and software, as well as end-to-end support and service.