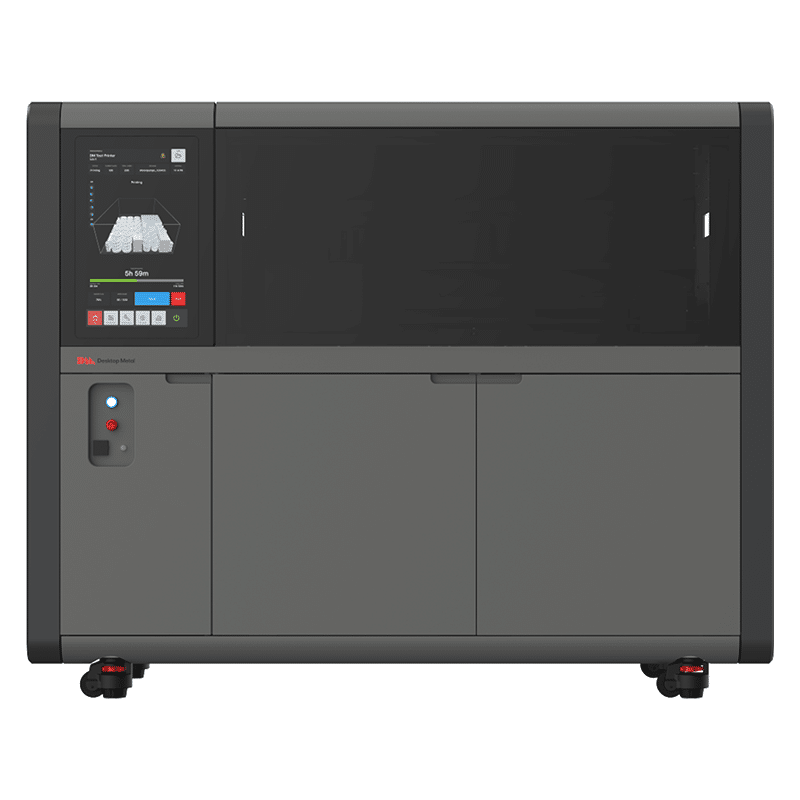

- Desktop Metal InnoventX

Specifications

- Print technology: Triple ACT (Advanced Compaction Technology)

- Print direction: Uni-directional (Bi-directional programmable)

- Binder jetting module: 1 piezo-electric printhead (256 nozzles)

- Max build rate: 54 cc/hr (3 in3)

- Print resolution:

- 80pL printhead – 400 dpi

- 30pL printhead – 600 dpi

- 10pL printhead – 800 dpi

- Layer thickness: 30 to 200 µm

- External dimensions: 47.5 x 36.8 x 56.5 in

- Build envelope: 6.3 x 2.5 x 2.5 in

- Power requirements:

- 120 V, 60 Hz, 1-phase

- 230 V, 50 Hz, 1-phase

Description

The X-Series family of scalable 3D printers — the InnoventX™, X25Pro™ and X160Pro™ — feature industrial piezoelectric printheads and patented Triple ACT advanced compaction technology, which dispenses, spreads, and compacts ultra-fine powders with tight parameter controls. Triple ACT allows these open-materials systems to process metals, ceramics and more with high density and repeatability for functional, precision parts and tooling in a wide range of build areas.

The InnoventX™ is most compact binder jet 3D printer for the production of metal, ceramic or composite parts. Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.

- Recommended Products