- technology review

When evaluating high-speed 3D printing to unlock production applications, there are a few technologies to consider. Join us as we compare the Nexa3D NXE400 and the Carbon M2.

nexa3d nxe400

Build Volume: 275 x 155 x 400 mm

Print Speed: up to 60cm / hour*

XY Resolution: 75µm

Minimum Layer Height: 50µm, 100µm

Material Pricing: $100 – $450 / liter

Connectivity: Ethernet, Wifi, USB

carbon m2

Build Volume: 189 x 118 x 326 mm

Print Speed: up to 20cm / hour**

XY Resolution: 75µm

Minimum Layer Height: 100µm

Material Pricing: $50 *** – $399 / liter

Connectivity: Ethernet, Wifi. Internet connection required.

- TECHNOLOGY

Traditional resin-based printing has always faced limitations for production applications because of its speed. High-speed printing technologies are driven by minimizing the time to print in the Z axis direction, delivering fast builds and allowing for isotropic properties. Both Nexa3D and Carbon have their own approach to delivering this speed.

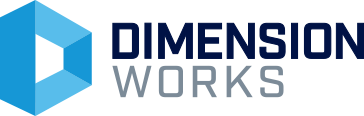

NEXA3D LSPC

Nexa3D’s LSPc approach delivers build speeds up to 60 cm per hour.

LSPc (Lubricant Sublayer Photo-curing) utilizes an LED light array which is masked to accurately control the position of light shining through. Their proprietary LSPc membrane prevents the part from sticking to the bottom of the vat, allowing resin to flow quickly beneath the part. The benefits are high-speed, accuracy and no visible layering.

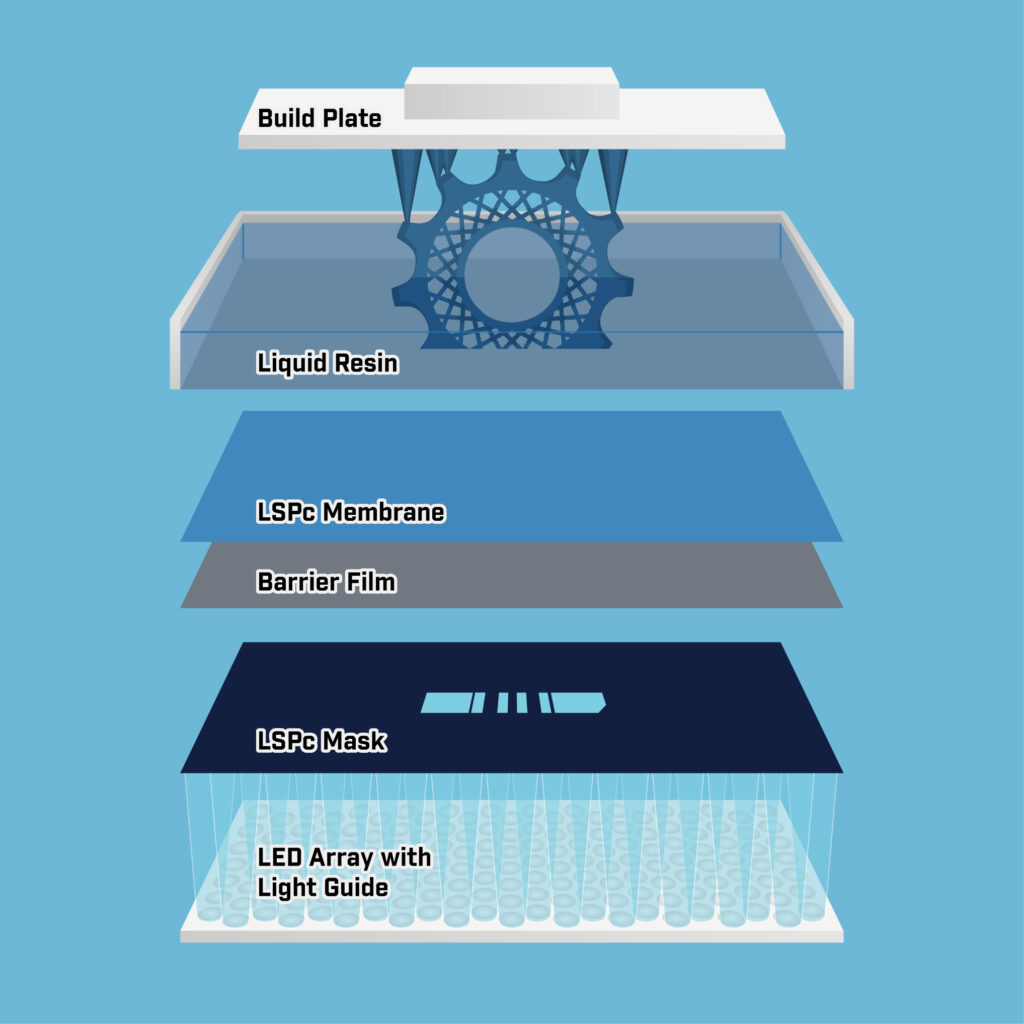

carbon CLIP™

Carbon’s CLIP™ method delivers speeds up to 20 cm per hour.

Continuous Liquid Interface Production™ (CLIP™) technology utilizes a chemical process in which oxygen and light are used to manage resin curing. The oxygen permeable window creates a “deadzone” at the bottom of the resin vat, enabling continuous printing without having to separate and reposition in between layers.

nexa3d nxe400 materials

20 materials available

Partnerships with DSM & Henkel

Options include High-Temp, Flexible, Prototyping, ABS-like, Medical, and Dental resins

1-part materials, allowing for re-use of residual material in the vat

carbon m2 materials

13 materials available

Partnership with Henkel

Options include High-Temp, Flexible, Prototyping, ABS-like, Medical, and Dental resins

1-part and 2-part materials. 2-part materials cannot be re-used once mixed

- Total cost of ownership

carbon m2

Carbon utilizes a subscription model for their printers. The Carbon M2 will cost you $50,000 per year with a minimum 3-year subscription. Carbon requires the purchase of the “Accessory Pack” for $12,500. The minimum total cost for 3 years is $162,500.

Professional installation and training is an additional $10,000. If you need the Carbon Part Washer, you’ll pay $10,000 per year.

In summary, a 3-year all-inclusive subscription of the Carbon3D M2 and all the preferable add-ons will cost you just under $200,000.

nexa3d Nxe400

At less than half of the total cost of the Carbon M2 subscription, the Nexa3D NXE400 is an excellent value.

The complete solution from Nexa3D includes the NXE400, installation, the xCure and xWash units for post-processing and is less than $80,000.