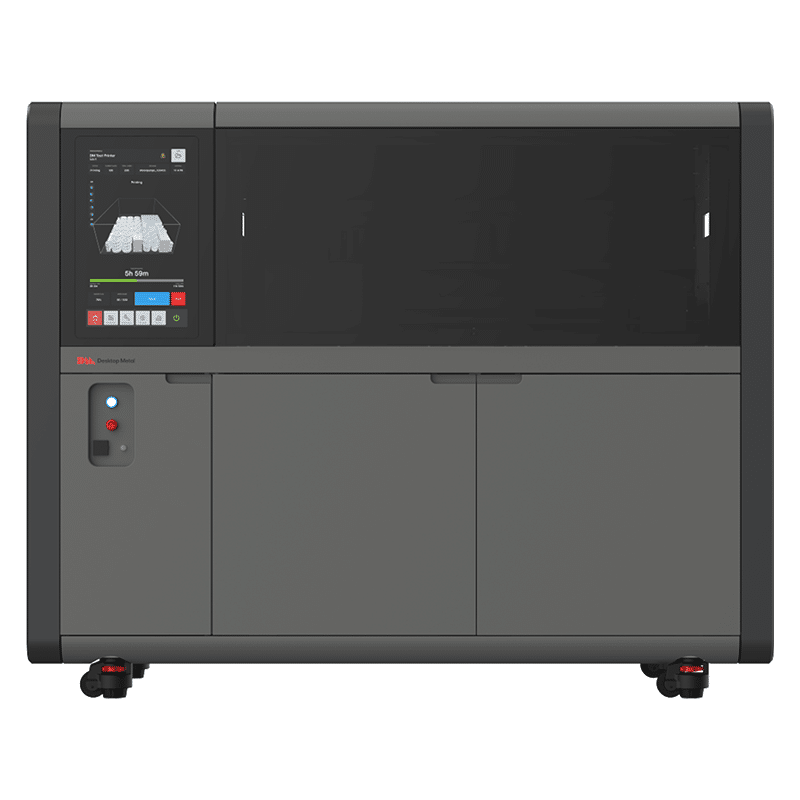

Designed with the modern machine shop in mind, the Shop System is built to fit seamlessly into your workflow. Produce parts with superior surface finish and resolution versus laser-based systems at a fraction of the cost.

Affordable turnkey solution

The Shop System contains all pieces of equipment your machine shop needs to begin binder jetting — from print through sintering. And with a range of build volume configurations (4L, 8L, 12L, and 16L), the Shop System is designed to scale to your shop’s throughput.

All inclusive system (printing through sintering)

Range of models: 4L, 8L, 12L,16L build boxes

Simplified post-processing

Parts on the Shop System print fully supported in their powder bed, and feature hand-removable sintering setters. Avoid hours of labor machining off support structures typical to laser-based systems and instead achieve customer-ready, near-net-shape parts right out of the furnace.

No print supports required

No EDM’ing support structures

Hand-removable sintering supports

Optimized powders & parameters

Get started quickly with a turnkey, end-to-end solution. Shop System features Desktop Metal engineered powders and processing parameters, optimized to deliver exceptional part quality, and ensure part-to-part repeatability.

Turnkey, end-to-end solution

Desktop Metal engineered powders

Unparalleled productivity

Amplify your shop’s output. Effortlessly print end-use metal parts with the quality, surface finish and tolerances required to co-exist with machining.

Up to 10X faster than laser powder bed fusion

Effortlessly print a batch of complex parts every shift

Produce new designs at the press of a button

Up to 10x faster

With a high-speed, single-pass print engine, the Shop System produces high-quality metal parts up to 10x faster than laser powder bed fusion—producing up to 70kg of metal parts per day.

Up to 10x faster than laser-based systems (1)

Print up to 70kg of parts/day

1. Based on published speeds of single-laser, mid-range laser powder bed fusion systems as of August 25, 2020.

Print a build per shift

Average cycle times of 6-12 hours enable a new build every shift. Print tens to hundreds of near-net shape parts each day and reserve machinist hours for refining critical features.

6-12 hour build time

Effortless productivity

Save machinist hours with near-net-shape parts

Flexible batch jobs

The Shop System is a tooling-free manufacturing process. Change over to a new job at the press of a button and process multiple complex jobs without the need for custom setups.

No tooling required

No custom set-ups required per design

Simultaneously produce multiple complex jobs

Easily switch powders in a single shift

Superior Print Quality

Print customer-ready, high-resolution parts with incredibly fine feature detail. Achieve surface finishes as low as 4µm Ra out of the furnace, and <0.1µm Ra with mass finishing. The Shop System produces fully dense, solid parts, no debind or infill required.

High resolution parts

Fine feature detail

Superior surface finish

High-resolution printing

The Shop System features the highest resolution single-pass binder jetting system in the market. With 1600×1600 DPI native (33% higher resolution than comparable systems1), and over 670M drops per second, the Shop System delivers high-speed, high-resolution printing.

1600 x 1600 native DPI

Over 670 million drops/second

Adaptive print engine

Users don’t have to sacrifice feature detail or resolution for speed. Employing the smallest droplet size of any single pass binder jetting system (~1 pL) and automated drop multiplexing up to 6 pL, the Shop System achieves superior surface finish, bleed control and rich feature detail at high speed.

Smallest droplet size (~1 pL)

Automated drop multiplexing

Surface finish as low as 4 µm Ra