- UltiMaker Factor 4

Specifications

Print Technology: Fused Deposition Modeling

Build Area: 330 x 240 x 300mm

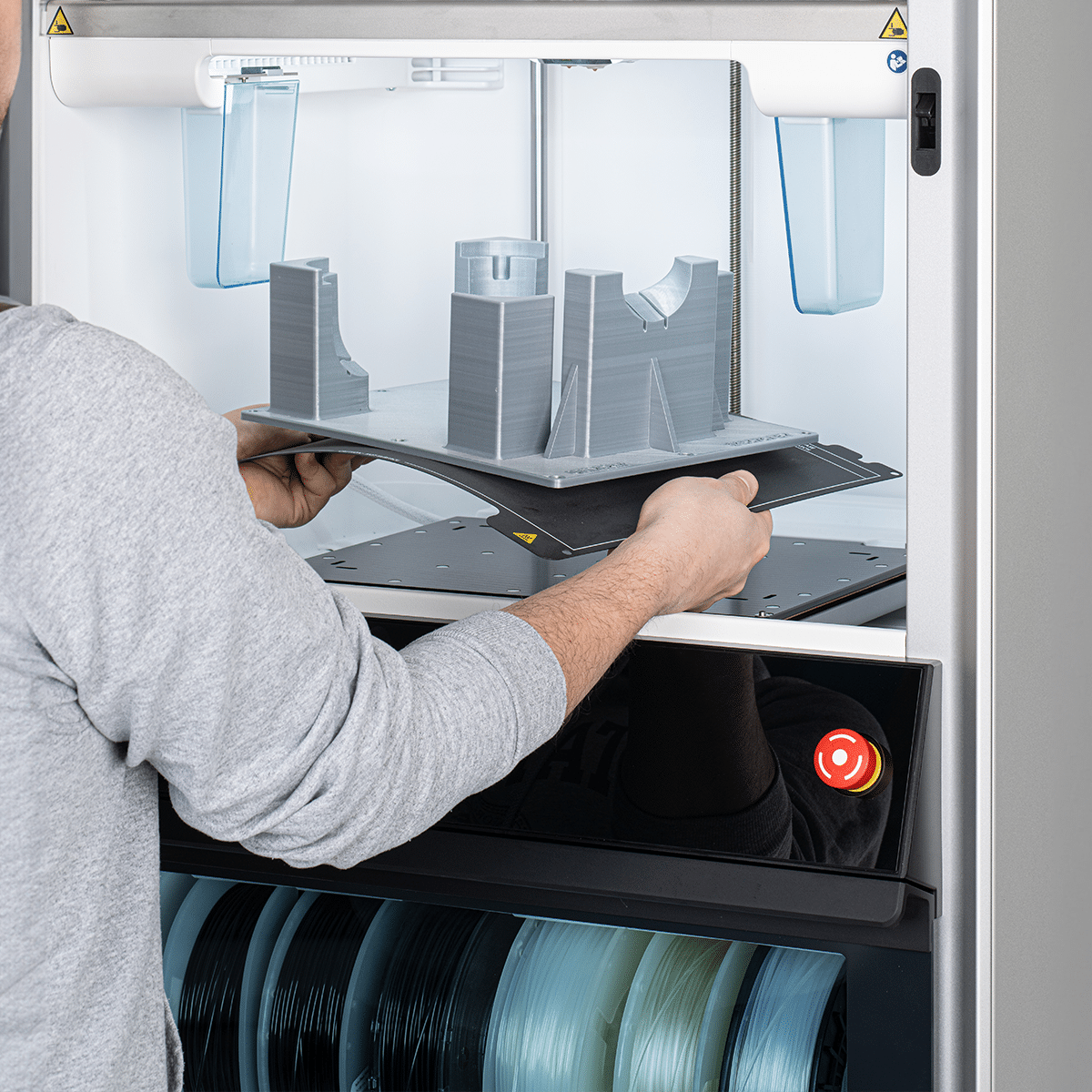

PEI coated flexible build plate (20-120C)

Actively controlled build volume temperature

Closed loop flow compensation

Layer resolution: Down to 20 micron

Print Temperature: Up to 340C with HT Print Core

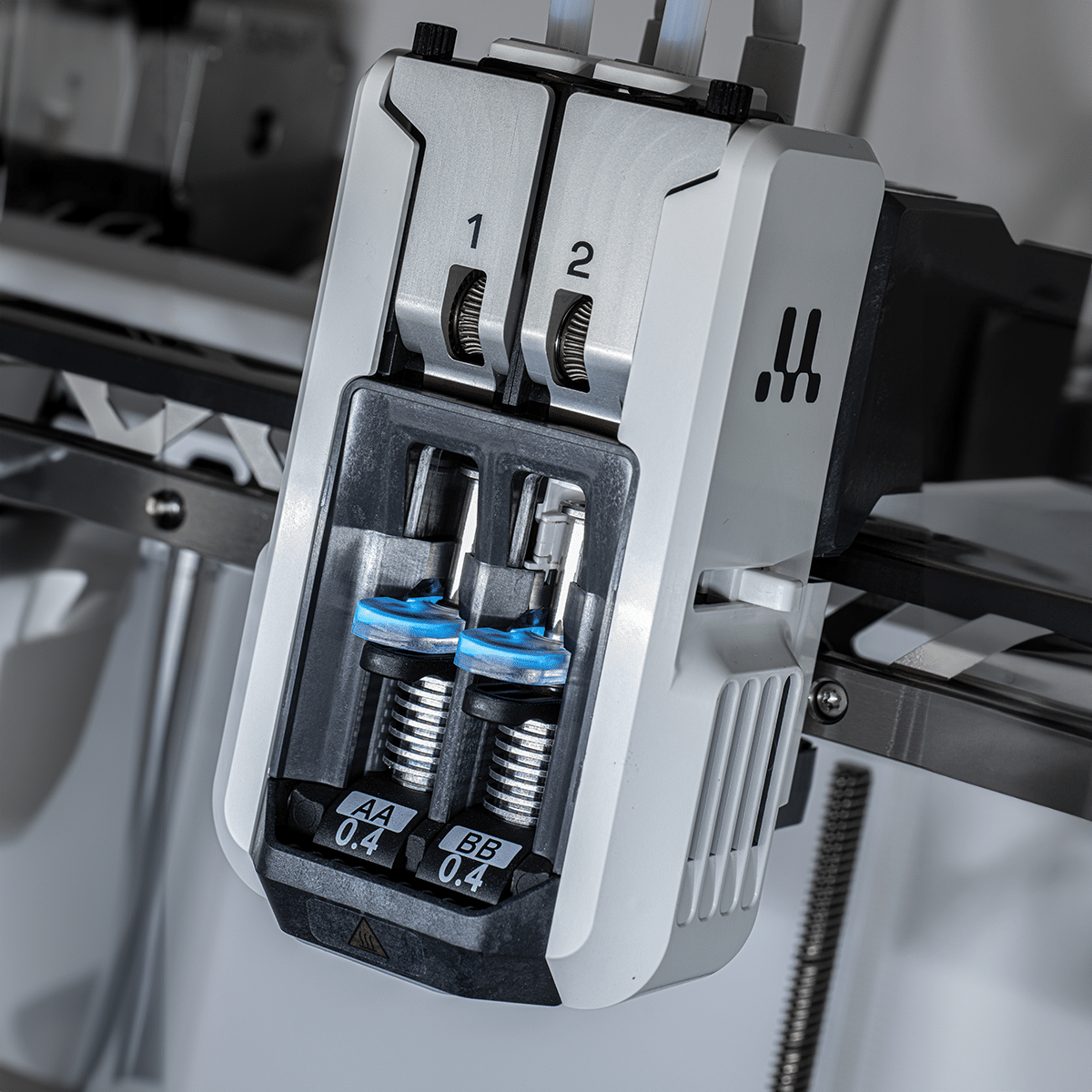

Dual Extrusion

HEPA H13 Filter

Connectivity: Wi-Fi, LAN, USB Port

Monitoring: Live Camera

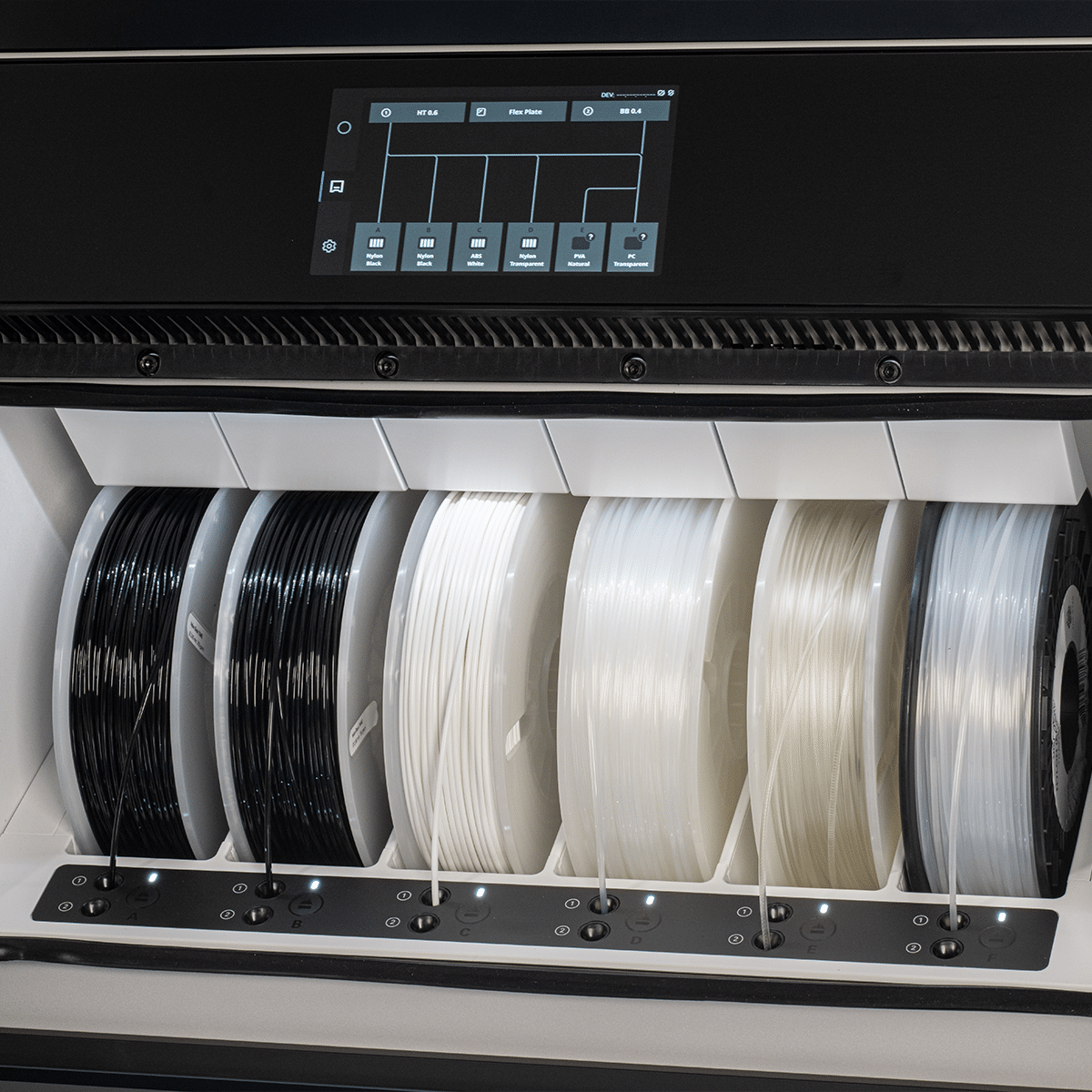

Material capacity: 6 spools

Material recognition: Auto-recognition enabled with NFC scanner

Feeder type: Direct Drive Print Head

$19,500.00

Free Shipping

Description

The UltiMaker Factor 4 is an end-to-end industrial application solution. It’s tailored for the development, production, and full-confidence deployment of process-critical tools and machine components. Factor 4 keeps operations running, simplifying processes in factories, and reducing human-triggered variabilities. It streamlines factory floor operations with support for engineering materials, direct dual material extrusion, and onboard print process reporting to achieve unrivaled predictability and minimal variance.

The UltiMaker Factor 4 delivers industrial-grade performance with reliable and repeatable results:

Edge-to-Edge dual extrusion.

A spacious build chamber and homogenous bed heating allows you to take advantage of every millimeter of the 330 x 240 x 300 build plate – regardless of what material you are using. This is dual extrusion with almost unlimited design freedom, maximizing what’s possible for each print job.

Automatic material handling and storage.

A new, integrated, automatic material handling system reliably manages your spools so you don’t have to. The internal chamber is kept at less than 15% relative humidity, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs.

Heavy duty. Heavy weight.

The UltiMaker Factor 4 is most at home in an industrial environment. Built from a robust steel, aluminum, and glass construction, it can be placed anywhere thanks to its triple-insulated and temperature-controlled build volume and integrated HEPA filter.

A simple, powerful addition to your workflow.

The Factor 4 is a 3D printer you can use with confidence. Its 7-inch capacitive touchscreen shows more real-time process data. Its door pauses a print when opened. And its large, red “stop” button makes operation safer if ever you need to quickly stop Factor 4 printing.

3D printing reliability and repeatability.

Factor 4 features in-depth, onboard reporting to ensure easy validation and quality control, making it the perfect choice for engineers seeking reliable and repeatable 3D printing. Tested to achieve over 95% print completion success* and dimensional accuracy within ± 0.2 mm ± 0.2 % of the feature nominal length, Factor 4 delivers consistent results across multiple machines – ideal for producing validated parts for distributed manufacturing.

*95% print success rate tested using UltiMaker PLA, Tough PLA, PETG, PET CF, and PPS CF.

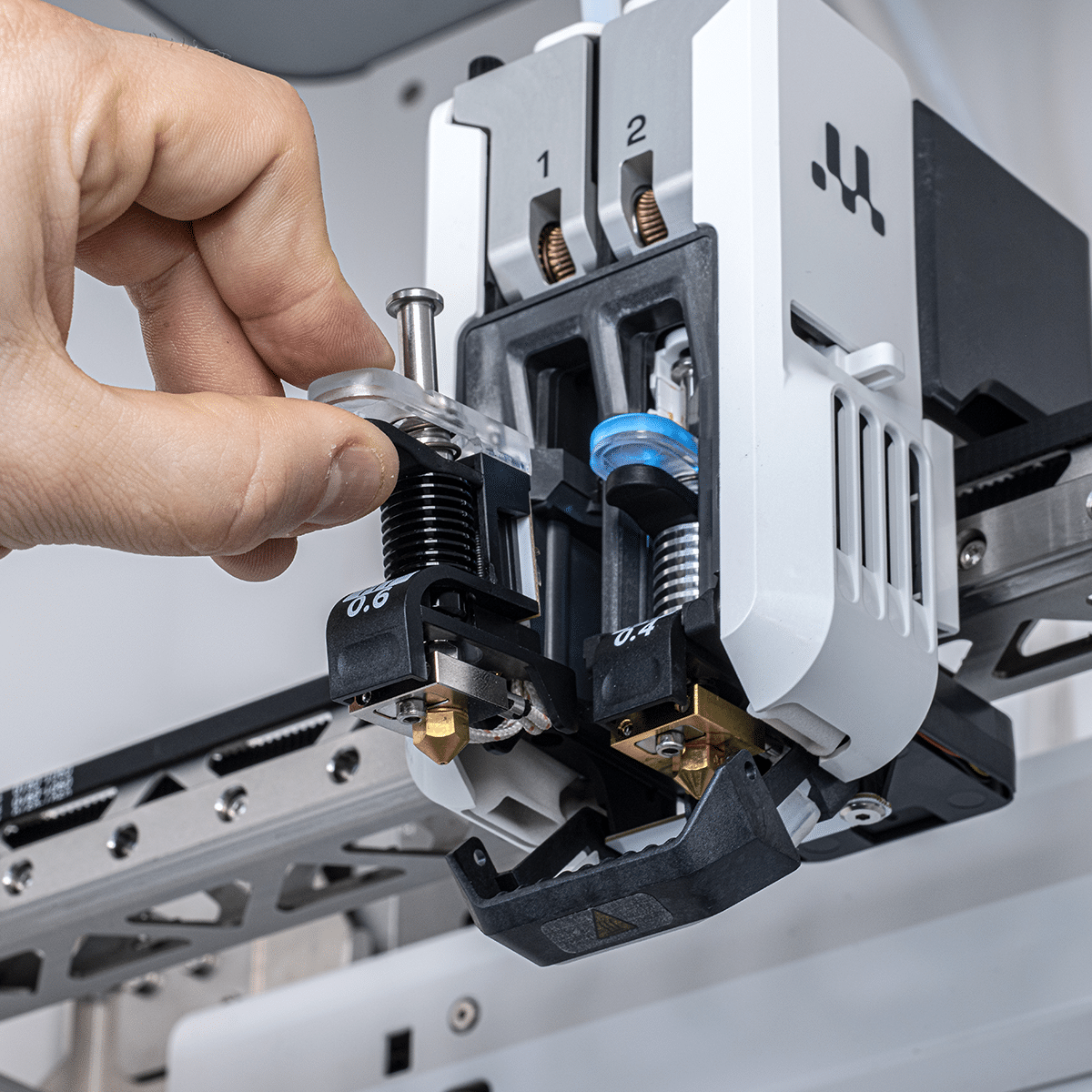

Direct drive extrusion.

The combination of the all-new H-bridge gantry, direct drive extrusion print head, and built-in accelerometer allows high-speed movement and position accuracy ± 0.2 mm or ± 0.2% of a certain feature nominal length with UltiMaker Verified Materials. This results in best-in-class dual material printing speeds so that you can quickly create the flexible or strong parts you need.

High-temperature 3D printing.

The UltiMaker Factor 4 raises the temperature up to 350 °C using the HT print core. This means that you can now 3D print higher temperature-resistant and durable materials with more confidence. The temperature within the fully enclosed build volume is also controlled up to 70 °C, with a heated bed up to 120 °C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

A hassle-free workflow.

When hardware, software, and materials are all developed under the same roof, you get a seamless 3D printing experience that’s always up to date. Whatever your Factor 4 setup, all UltiMaker materials and print cores are automatically recognized within UltiMaker Cura. And it’s incredibly easy to import CAD files and projects from leading software partners, like AutoDesk 360 and Trinckle.

Easy serviceability.

UltiMaker Factor 4 was designed to be modular. This means less production downtime in the event that a part of the printer needs servicing. Under the UltiMaker Factor 4 service plan, an expert technician anywhere in the world will be able to quickly swap the faulty part out for another so you can get up and running again as quickly as possible.

New printer. Same DNA.

Despite being an industrial-grade 3D printing platform, Factor 4 is an open system, allowing you to 3D print with the ideal materials to suit your needs. It is built on more than 13 years of UltiMaker legacy – dedicated to innovation, accessibility, and openness.

- Learn More

- Recommended Products